НАШИ УСЛУГИ

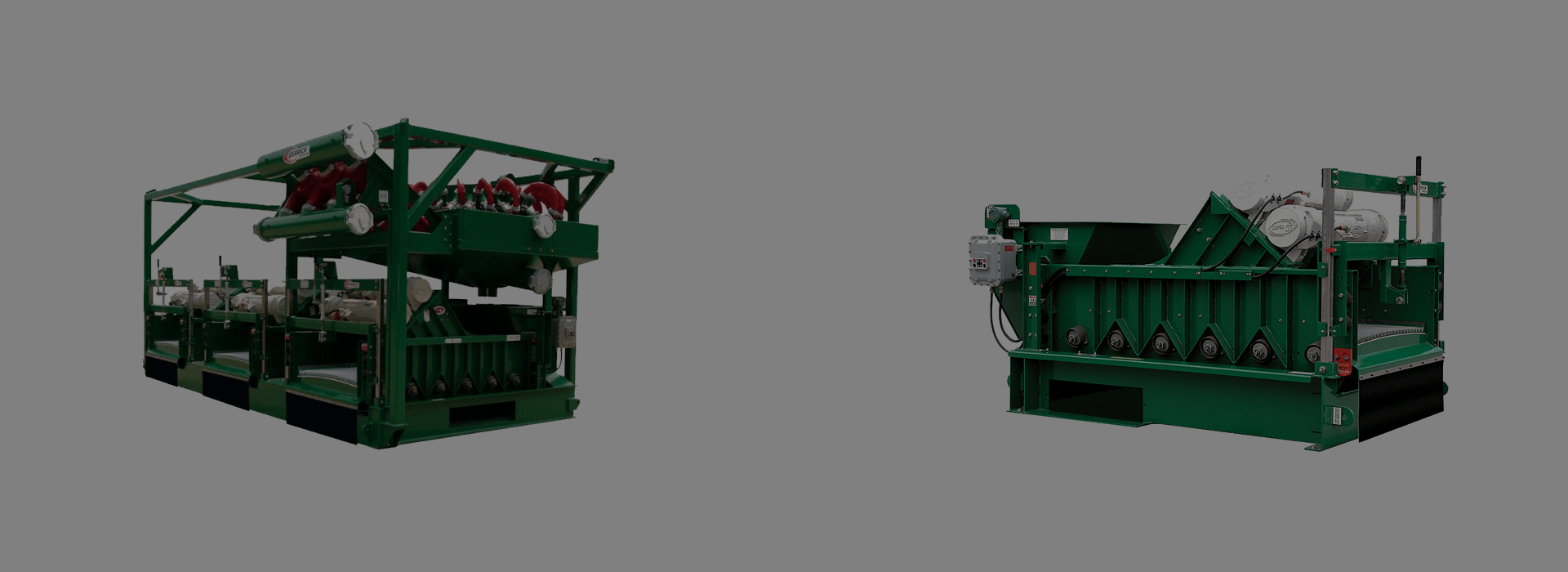

«Oмас Интегрейтед» способен поставить более чем 3000 наименований добавок для всех типов буровых растворов и жидкостей заканчивания, которые востребованы на рынке нефтегазовой отрасли.

Наша компания имеет обширный опыт бурения вертикальных и горизонтальных, наклонных и нагнетающих скважин глубиной более 5000 метров и углом наклона более 90º на нефтяных и газовых месторождениях Казахстана и странах СНГ.

Мы предлагаем своим заказчикам только высококвалифицированных специалистов. Все наши инженеры по буровым растворам прошли всестороннее обучение, имеют обширный опыт работы в данной специфике и способны вести работу на трёх языках. Наши специалисты обучены и имеют опыт предотвращения и ликвидации всех типов осложнений.

Для максимально эффективного удовлетворения производственных потребностей и ожиданий мы используем опыт технических консультантов со всего мира. Сегодня в нашей компании трудятся более 200 обученных и опытных инженеров по буровым растворам.

Наша компания использует собственный комплекс программного обеспечения «OmacPro» для сбора, классификации и анализа данных по буровым растворам. Программа разработана с целью автоматизации расчетов производственных процессов при бурении, является 100% казахстанской разработкой с учетом специфики и нюансов нефтегазодобывающей отрасли региона.

ҚАЗ

ҚАЗ РУС

РУС ENG

ENG